Download

S Series Engines

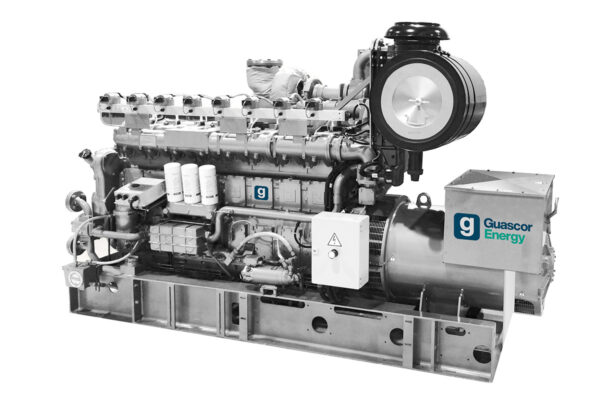

SL Engines

Ideal for power generation, cogeneration/trigeneration, mechanical drive and marine applications – the lean burn, electronically carbureted G-SL gas engines have an output range from 209 to 1150 kWb at 50 Hz and 60 Hz. Providing an excellent solution when fueled by natural gas, landfill and sewage gas, flare, well gas, and syngas, the SL Series is a cost-efficient choice in both implementation and service.

With great fuel flexibility and fuel blending availability for natural gas/biogas applications, this series is also an eco-friendly solution.

Along with fast start availability, a high load acceptance capability is one of the main features of this engine series. Robust, reliable, and with superb fuel flexibility, this Otto cycle turbocharged and charge-aircooled engine series features a single or double-circuit cooling system.

There is a high-temperature option in the main cooling circuit, with temperatures of up to 120ºC possible. If required, the auxiliary cooling circuit can deliver a different temperature.

The main cooling circuit may also feature an oil cooler. With a dry or wet exhaust manifold, single or double stage charge-air cooler and reduced oil consumption, this series of engines can include emissions control if required and is

compliant with the latest U.S emissions standards, being EPA certified for natural gas power generation, for example. Supplied as a standalone engine, genset or in a fully containerized unit, integrated GCS-E and GCS-G genset control systems are available for some applications.

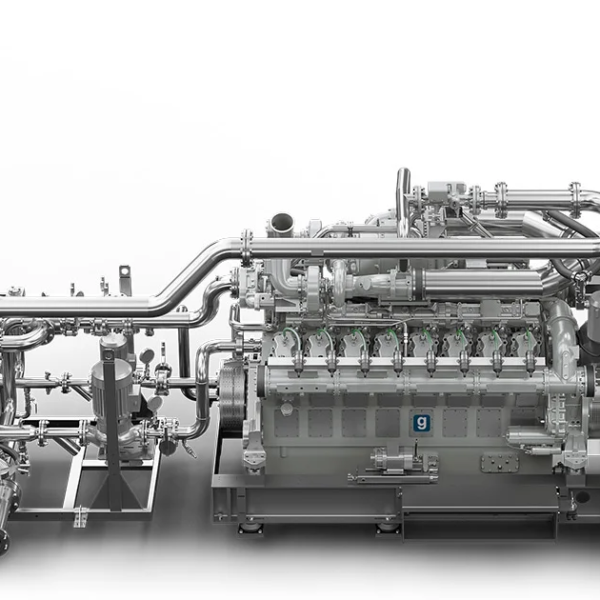

SM Engines

Lean burn and electronically carbureted the SM series of gas engines provide an excellent solution for power generation, cogeneration, and trigeneration applications.

Fueled by natural gas, landfill and sewage gas, and propane LPG, outputs range from 1055 to 1100 kWb when fueled with natural gas, landfill or sewage gas in 50 Hz and 60 Hz configurations. When fueled with propane or LPG, outputs are from 275 to 906 kWb at 50 Hz and 60 Hz, respectively.

This Miller cycle series of engines is turbo-charged and includes two-stage charge-air cooling if required. A double cooling circuit system allows different temperatures to be achieved in the auxiliary cooling circuit while an oil cooler is an additional option for the main cooling circuit. Among the key characteristics of this series of engines are standard interchangeable parts and very high operational availability – key competitive advantages.

With a dry or wet exhaust manifold configuration, an emissions control option means this series is compliant with the latest U.S. emissions standards and it has reduced oil consumption too. This engine series may be supplied as a stand-alone engine, as a genset, or as a fully containerized unit.

SR Engines

Robust and reliable, the rich burn, electronically carbureted SR Series gas engines offer great performance for power generation and cogeneration applications.

Outputs range from 180 to 870 kWb at 60 Hz and this series may be fueled by natural gas and well gas with superb fuel flexibility. This eco-friendly engine series meets the latest U.S. emissions standards and has great flexibility for load acceptance too.

Turbocharged and with single or double-stage charge-air cooling, the SR Series features a double-circuit cooling system in which different auxiliary cooling circuit temperatures are achievable. With a wet exhaust manifold, the SR Series machines are supplied as a stand-alone engine, as a genset, or as a fully containerized unit.